Get the most out of your learning with our

ACCESS-ALL SUBSCRIPTION

Subscribe to access all streamed video lessons

£18.99 per month

£18.99 per month

Preparing the Full Head Life Cast for Filling with Plaster

Neill Gorton

Preparing the Full Head Life Cast for Filling with PlasterThe steps taken to prepare a full head life cast that’s been taken with an alginate front and plaster bandage back, for casting a positive in plaster. Closing the nostril holes with alginate and joining to the two halves accurately and securing them ready for filling the cast with plaster.

Pouring Plaster into a Full Head Life Cast and Cleaning up the Cast

Neill Gorton

Pouring Plaster into a Full Head Life Cast and Cleaning up the CastFilling the full head life cast with plaster and then de-moulding the finished cast. How to use tools to refine and clean up the plaster cast, removing and correcting imperfections.

Prep of a Face Cast with Frame

Neill Gorton

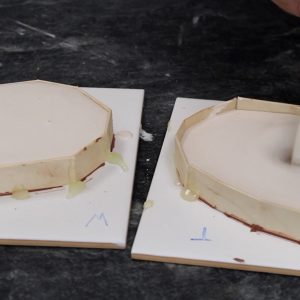

Prep of a Face Cast with FramePreparing a face cast that has been taken using the frame technique for casting in plaster. Reassembling the cast and securing the parts together ready for filling with plaster.

Prep of a Face Cast and Casting a Plaster Positive

Neill Gorton

Prep of a Face Cast and Casting a Plaster PositiveCasting a plaster positive of the face from an alginate face cast. De-moulding and cleaning up the plaster cast.

Mould Making Part One: Cheeks and Forehead

Neill Gorton

Mould Making Part One: Cheeks and Forehead Creating new cores to transfer the floated forehead and cheek appliance sculptures on to. We cast a rigid foam copy from the silicone negative mould and use this to help define the best shape and make a guide for producing plaster copies.

Mould Making Part One: Chin, Lips and Nose

Neill Gorton

Mould Making Part One: Chin, Lips and NoseCreating new cores to transfer the floated chin, lips and nose appliance sculptures to. We create snap moulds in alginate and cast plaster copies from these which are shaped in readiness for moulding in silicone and casting positives in PU resin.

Mould Making Part Two: Cheeks

Neill Gorton

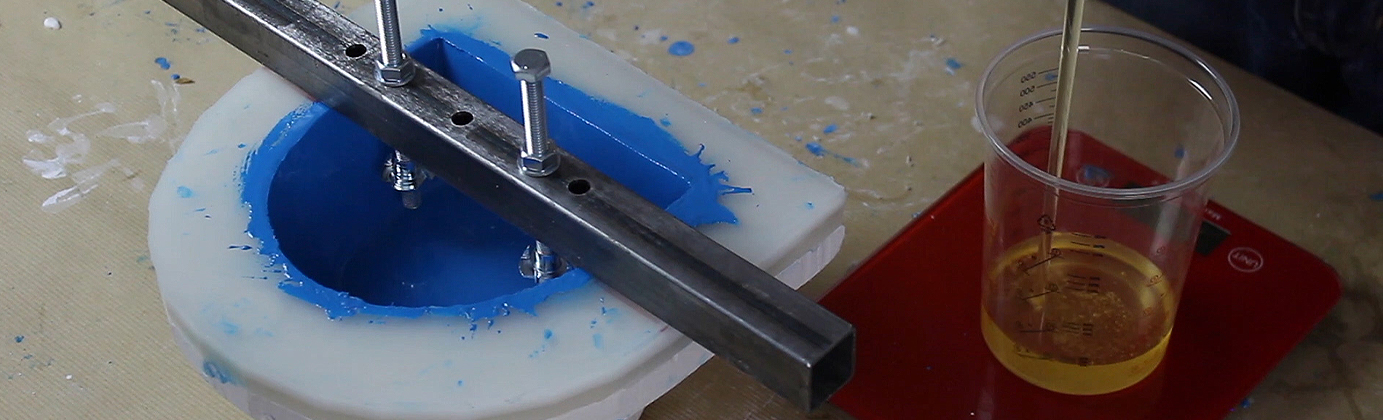

Mould Making Part Two: CheeksBlock moulding the cheek cores in silicone and casting them out in polyurethane resin.

Mould Making Part Two: Chin, Lips and Nose

Neill Gorton

Mould Making Part Two: Chin, Lips and NoseBlock moulding the chin, lip and nose in silicone using various found containers.

Mould Making Part Two: Forehead

Neill Gorton

Mould Making Part Two: ForeheadMaking a brush up silicone mould of the forehead core.

Mould Making Part Three: Cheeks

Neill Gorton

Mould Making Part Three: Cheeks Casting the cheek cores in polyurethane resin and using fillers.

Mould Making Part Three: Chin, Lips and Nose

Neill Gorton

Mould Making Part Three: Chin, Lips and NoseCasting the chin, nose and lip cores in a hard polyurethane casting resin.

Mould Making Part Three: Forehead

Neill Gorton

Mould Making Part Three: ForeheadCasting the forehead in a hard polyurethane casting back filled with a fast cast resin and filler. Inserting bolts to create screw threads for mould opening.

Casting a Plaster Cast out of a Permanent Mould

Neill Gorton

Casting a Plaster Cast out of a Permanent MouldHow to cast a plaster positive copy of a life cast from a silicone negative mould, making the cast hollow to reduce weight and make it more efficient for use when floating appliance sculptures.

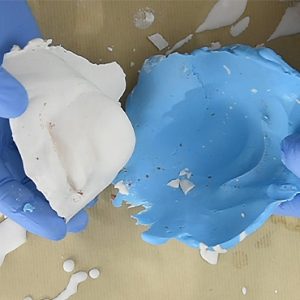

De-moulding the Prosthetic Moulds

Neill Gorton

De-moulding the Prosthetic MouldsOnce the moulds have completely cured, we now carefully open the moulds and clean them out in preparation for casting the silicone appliances.Making a Brush-Up Silicone Mould of a Life Cast

Neill Gorton

Making a Brush Up Silicone Mould of a Life CastThe process of mounting and extending a life cast in preparation for moulding and then moulding it using the silicone brush on method. This silicone mould is then supported with a plaster jacket.

Finishing and Texturing the Appliance Sculptures and Adding Flashing

Neill Gorton

Finishing and Texturing the Appliance Sculptures and Adding FlashingTaking the floated prosthetic sculptures and attaching them to the cores. Once attached all the finishing, detailing and texturing work is done before creating the cutting edge and adding areas of flashing in preparation for making a negative mould.

Moulding the Appliance Sculptures

Neill Gorton

Moulding the Appliance SculpturesPreparing the individual prosthetic appliance sculptures for moulding in polyurethane resin. Preparing the base and building retaining walls with mounting board.

Mountain Gorilla – Preparing the Sculpture for Moulding

Neill Gorton

Mountain Gorilla - Preparing the Sculpture for MouldingSealing the sculpture and dividing the sculpture up in to mould sections using metal shim. Incorporating keys into the shim.

Mountain Gorilla – Moulding the Sculpture in Fibreglass

Neill Gorton

Mountain Gorilla - Moulding the Sculpture in FibreglassFibreglass mould making. Applying gel coat and laminating fibreglass matting to produce a lightweight but durable mould.

Moulding and Casting a Basic Flat Mould Appliance

Neill Gorton

Moulding and Casting a Basic Flat Mould ApplianceTwo slightly different examples showing the process of making a basic silicone flood mould off a flat mould sculpture, and how to cast the silicone appliances in to those moulds.

Casting in Plaster from a Full Alignate Head Cast

Neill Gorton

Casting in Plaster from a Full Alignate Head CastCasting plaster into our full head alginate cast and looking at the results of our techniques of casting the nose separately and building a thickness behind the ears.

Casting Out from a Silicone Life Cast in PU Resin and Foam

Neill Gorton

Casting Out from a Silicone Life Cast in PU Resin and Foam Casting a head in fast cast PU resin and rigid foam from a silicone full head cast.

Mounting and Extending a PU Resin and Foam Head Cast

Neill Gorton

Mounting and Extending a PU Resin and Foam Head CastMounting, extending and preparing the resin and foam life cast in preparation for making a matrix mould.Silicone Flat Moulds of the Zombie Makeup

Neill Gorton

Silicone Flat Moulds of the Zombie MakeupBuilding containing walls and pouring the silicone for the flat moulds. How to ensure your walls are high enough to contain the amount of silicone needed.

Bigfoot – Preparing the Sculpture for Moulding

Neill Gorton

Bigfoot - Preparing the Sculpture for MouldingSealing the sculpture and dividing the sculpture up in to mould sections using metal shim. Incorporating keys into the shim.

Bigfoot – Moulding the Sculpture in Fibreglass

Neill Gorton

Bigfoot - Moulding the Sculpture in FibreglassFibreglass mould making. Application of a release agent followed by a gel coat and laminating fibreglass matting to produce a durable lightweight mould. Trimming and opening the mould.

Half Mask – Moulding the Sculpture in Plaster

Neill Gorton

Half Mask - Moulding the Sculpture in PlasterMaking a mould in plaster off of a clay sculpture. How to seal the clay, apply release agent and form plaster with reinforcement over the sculpture to create a negative mould.

Making a Brush Up Silicone Mould of Homo Habilis

Neill Gorton

Making a Brush Up Silicone Mould of Homo HabilisCreating a brush-up silicone mould from a WED clay sculpture using platinum silicone reinforced with fabric. The silicone mould is supported with a plaster multi-piece jacket.

Matrix Moulding the Cyclops – Part One

Neill Gorton

Matrix Moulding the Cyclops Part OneMatrix moulding from a WED clay sculpture. Matrix moulds provide a way of creating a more controlled thickness of silicone over the sculpture when making your mould. The process of making a matrix mould is slightly more involved than that of a brush-up mould but yields more superior and reliable results.

Matrix Moulding the Cyclops – Part Two

Neill Gorton

Matrix Moulding the Cyclops Part TwoMatrix moulding from a WED clay sculpture. Matrix moulds provide a way of creating a more controlled thickness of silicone over the sculpture when making your mould. The process of making a matrix mould is slightly more involved than that of a brush-up mould but yields more superior and reliable results.

Making Flat Moulds Using Plaster

Neill Gorton

Making Flat Moulds Using PlasterThe flat mould making process in its most basic form using plaster as a mould making medium.

Mountain Gorilla – Trimming, Opening and Cleaning the Mould

Neill Gorton

Mountain Gorilla - Trimming, Opening and Cleaning the MouldMaking the mould is only half the job. Once the fibreglass is cured, we tackle the messy process of opening and cleaning up the mould.

Mountain Gorilla – Creating the Core

Neill Gorton

Mountain Gorilla - Creating the CoreCreating a skin for animatronics requires a core to be fashioned inside the mould. This lesson covers the steps of modelling an appropriate skin thickness inside the mould, and casting the core in fibreglass.Moulding Homo Habilis Teeth in Silicone

Neill Gorton

Moulding Homo Habilis Teeth in SiliconeQuick, easy and effective silicone block moulds.